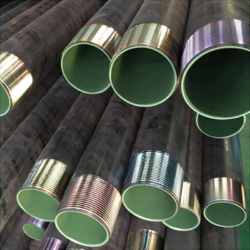

The inner coating of drill pipe can avoid the direct contact between the inner wall of drill pipe and corrosive drilling fluid, effectively alleviate the corrosion of drill pipe and reduce the flow resistance of natural gas. It is a significant measure to solve the corrosion fatigue failure of drill pipe and improve the drilling and production efficiency of natural gas. Sunrise Petro has abundant experience in supply of Internal coated drill pipe.

During the exploitation of sour oil and gas fields, the corrosion of drill pipes is quite serious. The main factors affecting the corrosion include H2S content, CO2 gas partial pressure, Cl concentration, ambient temperature and pressure. Coating to protect drill pipe has been widely used in oil and gas recovery. Among them, polymer epoxy resin and phenolic resin have become protective coatings with research and large-scale production value due to their good high-temperature and high-pressure resistance, chemical medium corrosion resistance and good adhesion.

Practice has proved that the drill pipe inner coating has good corrosion resistance, can prevent moisture, chlorine and corrosive media from entering the surrounding environment, and protect the drill pipe metal body. Internal coating is an important fortress for drill pipe corrosion and protection.

The following is Sunrise Petro coated layer performance data sheet.

| No | Item | Performance | Standard |

| 1 | Appearance | flat, even and smooth without defects such as bubbles and peeling | SYT-0544 |

| 2 | Dry film thickness | 200 ± 50um | SYT-0544 |

| 3 | Leakage point | None | NACE TM0384 |

| 4 | Adhesion | >= grade B | NACE TM0384 |

| 5 | Abrasion resistance | >= 2.0 L/um | SY/T 0315 |

| 6 | Roughness | liquid <=2.5um | JJG 2018 |

| powder <= 0.5um | |||

| 7 | Tensile property | Reach the yield strength of drill pipe without crack | SYT-0544 |

| 8 | Torsional resistance | Reach the yield strength of drill pipe without crack | SYT-0544 |

Features

1)Overall length polymer epoxy resin and phenolic resincoated

2) Anti-scaling

3)Anti-corrosion and anti-abrasion.

4) Both new and used drilling pipe available

Application

The internal coated drill pipe of Sunrise Petro is especially suitable for high water cut oil wells with high corrosion and prone to eccentric wear.

Sunrise Petro manufactures a variety of drilling pipes for oilfields including the common drilling pipe, Kelly bar, drill collar, and anti-corrosion and anti-abrasion drill pipe according to API 5DP and API 7-1.

These drilling pipes have diverse types to fit different environments and applications.

The company has an R & D center with a team composed of domestic authoritative professors and senior engineers to provide users with high-performance and practical products.