With the increasingly difficult exploration and production of oil and natural gas, deep wells, horizontal wells, extended reach wells, sulfur-containing wells and low-temperature wells have higher and higher requirements for drill pipes. Carbon fiber composites are suitable for various complex working conditions with their excellent characteristics. Sunrise Petro can supply carbon fiber reinforced plastic drilling pipe to meet the specific needs of clients to all over the world.

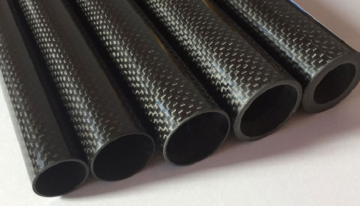

In recent years, Sunrise Petro has developed and produced carbon fiber reinforced plastic composite drilling pipe according to the actual needs of different working conditions. The principles of CDP(composite drilling pipe)are with high temperature curing the metal core shaft, and then extract the core shaft, the curing of the pipe section to complete the processing. Final preparation involves the addition of standard elastomeric centralizers before the pipe is run in the hole.

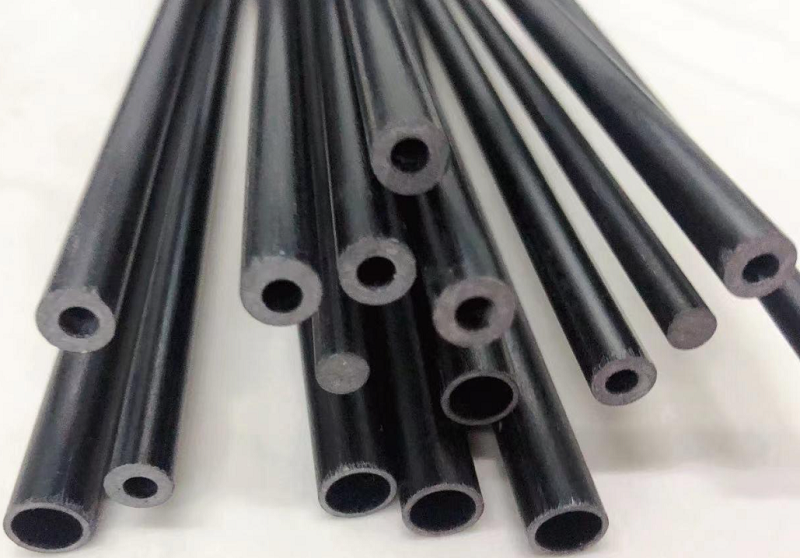

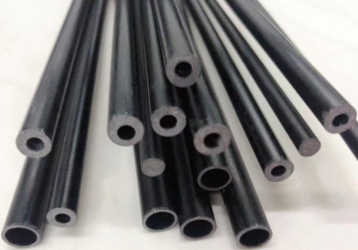

The carbon fiber composite drill pipe is composed of a carbon fiber composite pipe and a steel joint. It is necessary to ensure the sealing of the pipe and the joint, and coat the wear-resistant material outside. In terms of density, the density of carbon fiber composite material is about 1 / 4 of that of steel. Under the same strength and length, the weight of carbon fiber composite drill pipe is greatly reduced. For deep wells, the reduction of drill pipe mass means that the existing drilling capacity can be used to drill deeper distances.

Feature and advantage

1) Higher strength

The tensile strength of carbon fiber is more than 3500MPa, up to 5.5 GPA, and the general tensile strength of carbon steel is 235mpa. From the perspective of material alone, the strength of carbon fiber composite drill pipe is far higher than that of ordinary steel. With the excellent performance of material foundation as support, carbon fiber composite drill pipe can improve the drilling capacity of extended reach well, ultra deep well and deep directional well drilling.

2) Strong corrosion resistance

Carbon fiber itself is a microcrystalline structure similar to graphite crystal, which has high medium corrosion resistance and can still work normally in complex and harsh environments.

3) High fatigue strength

Carbon fiber drill pipe has higher fatigue resistance and longer service life.

4) Non-magnetic and convenient for downhole measurement

Optical cables or wires can be conveniently placed in the wall of carbon fiber composite drill pipe, which can realize the bidirectional high-speed communication function of downhole and ground data.

Application

Extremely suitable for deep wells, extra deep well, horizontal wells, extended reach wells and sulfur-containing environment.

Sunrise Petro manufactures a variety of drilling pipes for oilfield including the common drilling pipe, Kelly bar, drill collar, anti-corrosion and anti-abrasion drill pipe according to API 5DP and API 7-1.

These drilling pipes have diverse types to fit different environments and applications.

The company has an R & D center with a team composed of domestic authoritative professors and senior engineers to provide users with high-performance and practical products.