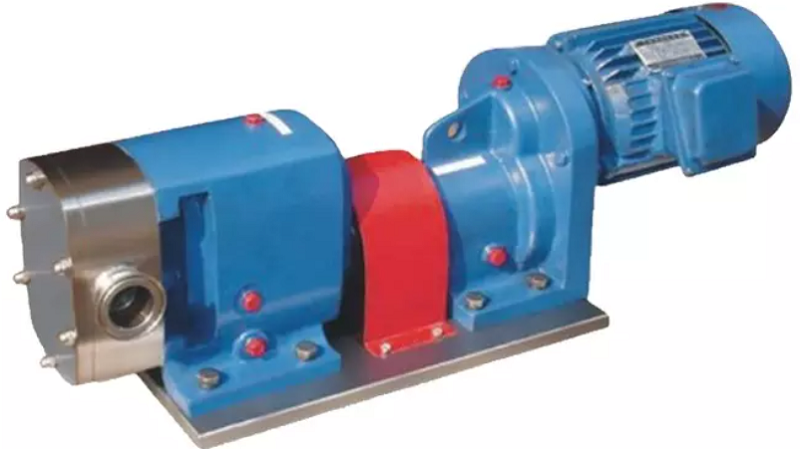

Cam rotor metering pump, also known as colloid pump, three leaf pump, sole pump, relies on two rotors (2-4 teeth) rotating synchronously and reversely to generate suction (vacuum degree) at the inlet during rotation, so as to absorb the materials to be transported. Sunrise Petro can produce the high-quality cam rotor pump for metering to meet the requirements of different application scenarios.

Working principle

During operation, the cam rotor pump of Sunrise Petro is to take the twisted rubber cam rotor pump as the core, and use two spiral cam rotors driven by synchronous gears to push the transmission medium from the pump inlet to the pump outlet. Because of the perfect sealing between the rotor rubber impeller and the pump body, the pump inlet and outlet chambers are completely separated, with strong vacuum pumping capacity. Therefore, the self-priming capacity of the pump is far greater than that of other types of pumps.

Since the three blade 60 ° spiral rotor is adopted, the instantaneous design flow of the pump is constant at every moment during the rotation cycle, with almost no pulsation and disturbance. The structure of Sunrise Petro cam rotor pump is completely symmetrical, and the delivery direction is reversible. Just change the driving direction, positive transmission suction and reverse rotation can be used for flushing.

Technical Feature

Sunrise Petro cam rotor metering pump has the following features.

Application

Sunrise Petro can supply a variety of metering pumps including Positive displacement metering pump, plunger metering pump, diaphragm metering pump, bellows metering pump and others. Metering pumps of Sunrise Petro are made of high quality carbon steel and alloy steel according to API Spec 675 standard.

With its enterprising spirit and scientific and rigorous management,Sunrise Petro has become a reliable metering pump supplier in China.