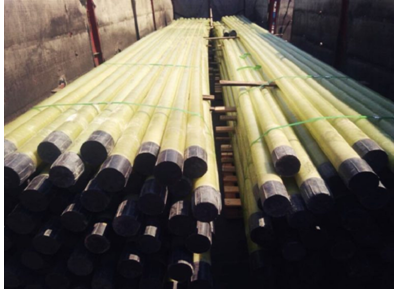

Compared with metal materials, FRP products have unique advantages such as light weight, corrosion resistance and good fatigue performance. After more than ten years of development and research, FRP sucker rods have been successfully trial manufactured with FRP materials. Field application shows that FRP sucker rods have great development potential. Sunrise Petro can supply FRP sucker rods to meet the specific needs of clients to all over the world.

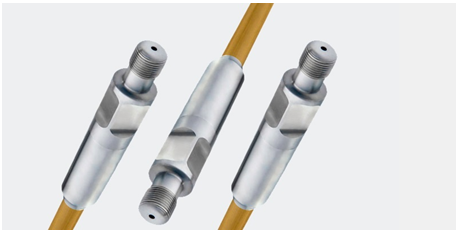

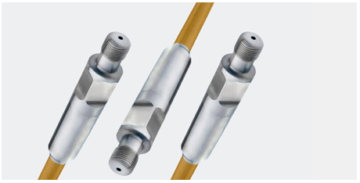

The full name of FRP sucker rod is fiberglass-reinforced plastic sucker rod, which is made of resin and glass fiber in a certain proportion through special pultrusion and curing process. This sucker rod is composed of FRP rod body and steel joint with external thread at both ends. The steel joint complies with the size, material and structure of sucker rod joint specified in API standard.

Structure

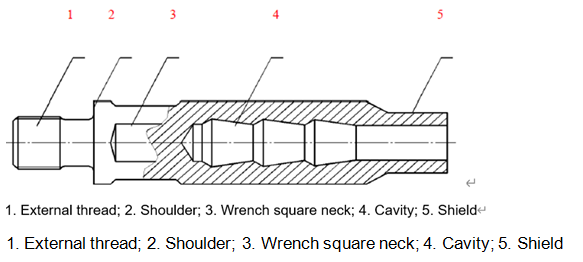

The following figure shows the basic structure of fiberglass-reinforced plastic sucker rod.

The inner cavity of the steel joint mentioned above is composed of several conical surfaces. By using special bonding technology, the epoxy resin adhesive is firmly adhered to the FRP rod to form a corresponding conical surface. During service, the multi-level conical surface of the inner cavity of the steel joint and the epoxy resin adhesive bears the working stress

The strength grade of the end joint, i.e. tensile strength, is divided into A&B. 620 to 793mpa for class A and 793 to965mpa for class B.

Features and relevant application

1) The weight of FRP sucker rod is light. The density of FRP sucker rod body is smaller and the weight per unit length of metal joint is about 1 / 3 of that of ordinary steel rod.

2) The elastic modulus of domestic grade D sucker rod material is 20.86 × 104mpa, while the elastic modulus of FRP rod material is 4.96 × 104mpa, only 1 / 4 of the elastic modulus of grade D rod, so the FRP sucker rod has better elasticity.

3) Corrosion resistance, reduce the breaking accident of sucker rod The FRP sucker rod has good corrosion resistance. The rod head is made of Grade K steel for sucker rod, which is corrosion resistant. Therefore, the FRP sucker rod is especially suitable for use in acid oil wells, including hydrogen sulfide and carbon dioxide.

4) FRP sucker rod can’t bear axial compression load. Since the FRP rod can’t bear the axial compression load, it is generally used as a mixed rod column with the steel rod, and the proportion of the FRP rod in the mixed rod column shall be increased as much as possible under the condition that the FRP rod is not under pressure

Sunrise Petro can supply API Sucker rod including the common sucker rod& pony rod, polished rod and sinker bar. Based on API Spec 11B and SY / T 5029 specifications, Sunrise Petro also developed a series of special sucker rods suitable for different well conditions, especially under high corrosion and high load conditions for oil well.

Our technical staff is ready to provide assistance in selection and design.With inventory and field sales support in strategic location, we are ready to respond in a timely professional manner 24 hours a day.