Tool joints are heavy-duty joint elements for drill pipe. The pin section of the joint is attached to one end of a length of drill pipe by friction welding, while the box section is attached to the other end. Sunrise Petro has own tool joint manufacturing factory, which can produce according to standards and client requirements.

Tool joints are usually made of heat-treated special alloy steel, which is stronger than pipe body steel. The large diameter section of the tool joint provides a low stress area where pipe wrenches are used to grip the pipe. Therefore, relatively small cuts made by the pipe wrench do not significantly affect the strength or life of the drill pipe joint.

Tool joints, when threaded, provide a high-strength, high-pressure connection that is strong enough to withstand multiple tightening and loosening cycles at drill holes and threads. A hard metal finish is often used in the band around the outside of the tool joint to make it resistant to wear from the borehole wall.

Types

According to API standards, the main types of joints are IF, FH, SH, REG and NC.

Basic structure

The following is the basic structure diagram of the tool joint which shows the cross section and upset section.

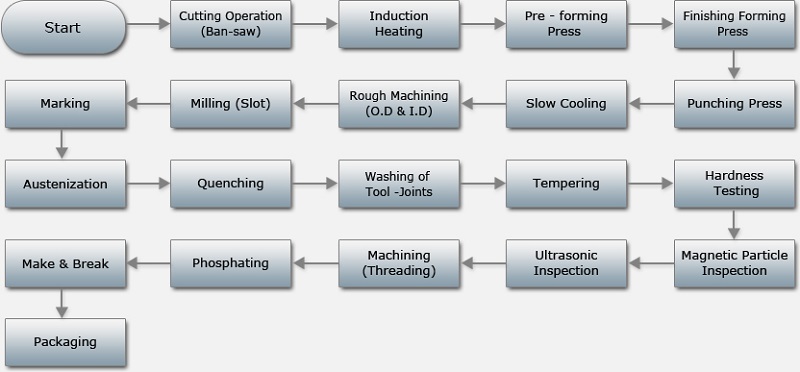

The following is the general processing flow of drilling tool joints.

Sunrise Petro manufactures a variety of drilling pipes for oilfield including the common drilling pipe, Kelly bar, drill collar, anti-corrosion and anti-abrasion drill pipe according to API 5DP and API 7-1. These drilling pipes have diverse types to fit different environments and applications.

The company has an R & D center with a team composed of domestic authoritative professors and senior engineers to provide users with high-performance and practical products.